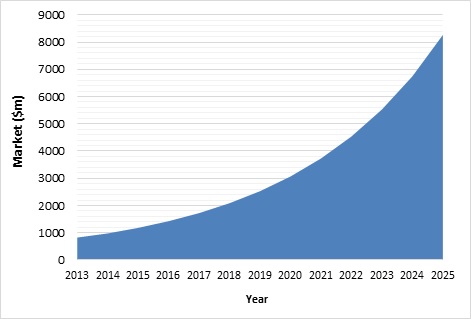

3D printing materials market expected to reach $8bn by 2025

According to a report published by IDTechEx, the 3D printing materials market is expected to increase from $800m in 2013 to $8bn by 2025. 3D printing is already common in aerospace, orthopaedic, jewellery and dental sectors, and is becoming more common in education, military, architecture, medical research and automotive sectors. This is because 3D printing is no longer used just for one-off pieces and prototypes, but for final part production of items with reduced and simplified assembly, quicker design iterations, greater design freedom, mass customisation and minimal material wastage. The report, titled ‘3D Printing Materials 2015-2025, Status, Opportunities, Market Forecasts’, discusses 3D printing in these sectors.

Due to the increased interest in 3D printing, a wider variety of materials are being used. The advantages and disadvantages of printing in different materials, the applications of each, and technical data on the properties of 3D printed materials are considered in IDTechEx’s report. The market value and volume of photopolymers, thermoplastic filaments, thermoplastic powders, metal powders, sand and binder, welding wire and plaster are discussed. These seven key materials have a total market of $800m which is expected to grow to over $8bn by 2025. ‘3D Printing Materials 2015-2025, Status, Opportunities, Market Forecasts’ also considers emerging 3D printing materials including electrically conducting materials, silicone, biomaterials, carbon fibre, regolith, ceramics and graphene.

Many of the key metal printer manufacturers are based in Europe and sell predominantly to European customers, therefore, Europe buys a higher share of metal powders than of other materials. In Asia, sales of thermoplastics are smaller than in North America or Europe as the hobbyist market has not really taken off.

Like with 2D printers, several major printer manufacturers are only allowing customers to use their 3D printing materials with their printers, however, any printing materials can be used with cheaper printers. Therefore, the value chain for 3D printing materials is complicated. To demonstrate the long term market of each value chain, the report forecasts each approach separately.

Although the growing market provides room for new players, it also provides room for acquisitions of small materials' formulators by printer manufacturers. IDTechEx’s report includes information on start-ups, closures, mergers and acquisitions. Following interviews with more than 50 key players in the industry, sixteen materials' suppliers are discussed in detail.

According to the report, desktop thermoplastic recyclers, cheaper ways of producing metal powders, other types of printing technology and competing prototyping technologies have the potential to dramatically change the 3D printing materials market.

‘3D Printing Materials 2015-2025, Status, Opportunities, Market Forecasts’ includes interviews with eight industrial end-users who describe their experiences with 3D printing, providing insight into their needs. Large industrial users require larger build volumes, increased build speed, greater precision, declarative CAD and movement away from layered structures which have anisotropic properties. Hobbyist users require cheaper printers and simpler CAD software.