Flexible printed circuits reach further into emerging applications

Flexible printed circuits can help to save weight, increase reliability, and enhance the functionality of electronic assemblies and interconnects. New manufacturing techniques now enable FPCs of unlimited length to address emerging applications in demanding sectors such as aerospace and automotive. Philip Johnston, CEO, Trackwise explains more.

The flexible printed circuits (FPC) are an established substrate technology, frequently used to support and connect electronic components in the same way as a rigid circuit board, or to connect sub-assemblies in the same way as a cable or wiring harness.

Product designers often choose to specify an FPC where space is limited, where assembly is difficult, or where connections need to move or bend during use. The FPC can also be folded and shaped to fit specific form factors or inside curved or aerodynamic structures, and bonded in place, which may be impossible with conventional PCBs and cables. As a wire harness replacement, FPCs can save weight and reduce bulk, as well as increasing reliability and lowering the bill of materials (BOM) by enabling interconnects to contain fewer connectors and electrical joints.

Also, final product assembly can be made simpler and faster, with fewer component parts and no need to colour code or label wired connections. Reduced manual intervention also helps improve repeatability. As a result, installation costs can be lowered, assembly yield can be increased, and the number of failures in the field reduced.

A wide variety of FPC materials and fabrication processes have been developed, which allow designers to optimise electrical and mechanical properties for the intended application. The flexible substrate is typically a polyester or polyimide, which acts as a carrier for the etched conductor. Advanced polymers are also now emerging to address opportunities such as high temperature applications or wearable electronics.

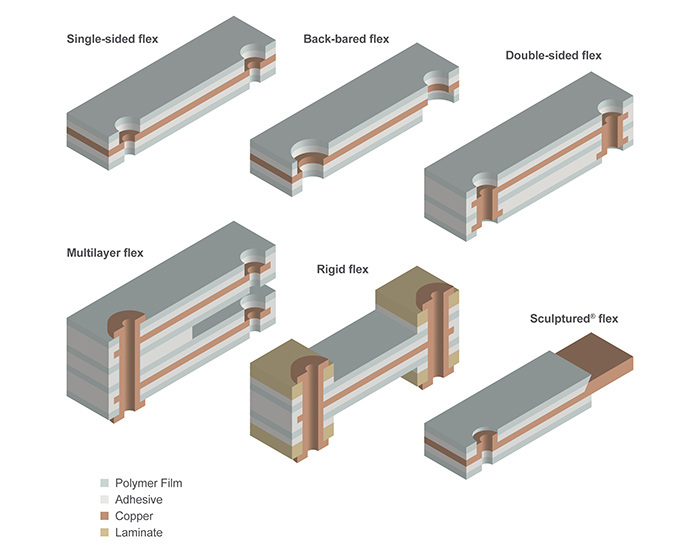

FPCs can be made in various forms, including single or multi-layer, single or double sided, or hybrid interconnects that combine rigid and flexible regions in a single, laminated structure. A single-layer FPC can be as thin as 25µm or less. Multilayer FPCs are typically a bonded construction made from several single- or double-sided flexible circuits comprising conductive and insulating layers. Plated through holes are typically used to interconnect conducting layers, and terminations may be applied on one or both sides. A protective cover layer may also be applied.

Above: Basic FPC construction

In the application, flexible circuits may be static - intended to be flexed once when installed during final assembly, or repair or servicing, of the product - or dynamic. In a dynamic design the circuit is intended to flex during normal operation, such as when used to connect electronic circuitry mounted on a moving sub-assembly like a car door, laptop display, or mass-storage disk read/write head. In a laptop display application, the FPC can be folded to pass through the hinge, allowing a slim, attractive design that can withstand many thousands of open/close cycles.

In addition, FPCs lets designers apply a variety of techniques to optimise signal integrity. Crosstalk and noise are more easily controlled using a uniform conductor pattern in the flex circuit. Multiple ground-plane options are practicable, such as lightweight cross-hatched, solid copper, aluminium or lightweight shielding films. Stitching vias and internal guard rails can provide continuous all-round shielding, with plated vias along the length of the circuit.

EMC performance is also good, as the small ground loop created by the guard traces minimises radiated emissions, and differential-mode transmission losses are low. In data-bus applications, impedance characteristics can be controlled accurately, transmission losses reduced, and radiated-field emissions lowered due to shorter current return paths.

Above: Six main types of FPC are commonly used, each with specific benefits and characteristics, depending on application needs

Today, FPCs of all types, worth billions of dollars in total, are installed in a wide variety of products from consumer devices such as smartphones, cameras, and game consoles, to IT equipment, industrial machines, and automotive, medical, aerospace, and satellite applications.

Wearable devices such as chest straps and wrist bands for sports and health monitoring are another obvious application opportunity. On the other hand, tiny devices such as hearing aids, heart pacemakers and medical pumps owe some of their compactness, comfort and convenience to FPC technology. Ultra-thin, flexible substrates are an important enabler for smart skin patches used to monitor blood sugar or dispense medication, as well as RFID smart labels for security, anti-counterfeiting and transport logistics and tracking applications.

Summary: 10 Key Strengths of FPCs

- Save space due to very thin, formable and bondable substrate

- Save weight with fewer connectors and fittings, reduced copper content

- Easier, faster product assembly

- Foldable and bendable to fit small housings

- Dynamically flexible

- Increased reliability; high vibration and shock resistance

- Better heat dissipation and current-carrying capability than wire harnesses

- High temperature stability, especially polyimide materials

- Lower stresses due to thermal mismatch

- Allows design for optimum EMC and noise performance

Any FPC project should be planned carefully, beginning with proper analysis to ensure that FPCs are the most suitable solution for the application. A detailed design process is recommended, considering factors such as the end product requirements, operating environment, mechanical and electrical requirements, and assembly methods. Close liaison with the FPC manufacturer is essential to ensure all aspects are adequately addressed, resulting in a specification that enables the FPC manufacturer to validate the design and provide accurate quotations.

Breaking the length barrier

Until now, traditional manufacturing processes have restricted the maximum practical FPC dimensions to about 610mm in length, with only a few exceptions.

A new and patented process known as improved harness technology (IHT) now enables printed circuit manufacturers to produce multi-layer FPCs of any length. Moreover, as a roll-to-roll manufacturing process, IHT is highly automated and therefore enables these large FPCs to be produced cost effectively. With this, product designers can now leverage the strengths of FPCs in a much wider range of applications, particularly in sectors such as medical, automotive, telecommunications, aerospace, transportation, industrial, and smart infrastructure.

Unlike conventional FPC manufacturing carried out using equipment that performs processes on materials held in a fixed, static position, IHT is performed with advanced machinery and custom software designed for the dynamic processes required to manufacture FPCs of indeterminate length. Moreover, materials are used in roll form unlike the fixed-size sheets supplied for conventional FPCs.

Addressing emerging applications

IHT is extremely well suited to replacing conventional wire harnesses with lighter and better performing FPCs. Typically, connectors are the only components added to the substrate, although the opportunity arises to create smart harnesses by populating the FPC as a printed-circuit with surface-mount or through-hole components such as sensing or signal conditioning devices.

In automotive applications, today’s cars can contain as many as 100 electronic control units handling features such as engine management, passive and active safety systems, and passenger comfort systems. In some high-end models, conventional interconnects can contain more than one mile of copper cabling comprising over 1,000 individual wires. The ability to create FPCs of unlimited length, using IHT, enables one-piece interconnects to replace conventional wiring looms with a simpler, more lightweight, and more reliable alternative. Looking ahead, the number and complexity of automotive interconnects is set to rise with the influx of electric and autonomous vehicles. In electric vehicles, FPCs produced using the IHT process enable power, control, and monitoring circuits to be integrated in high- and low-voltage harnesses for electric vehicle battery packs.

Similar advantages can be gained in the civil aerospace sector, where saving weight is a central goal to enable aircraft operators to reduce operating costs and emissions. Flexible circuits have been shown to reduce weight by up to 75% over traditional wire harnesses in aerospace applications. A single flexible circuit structure can now be produced using IHT to span an entire wing, or to reach from nose to tail of the aircraft.

Trackwise recently helped develop a ten metre long, six-layer, arc-tracking compliant harness for a commercial airliner, made possible using IHT. Even more dramatic projects include a 26 metre long shielded FPC for transferring power and signals across the wingspan of an unmanned aerial vehicle (UAV).

Conclusion

The light weight, ease of use, and high reliability of FPC substrates are already appreciated in the aerospace and automotive sectors. Now that IHT has been perfected, enabling cost-effective fabrication of extremely long FPCs up to several tens of metres, future medical devices, electric vehicles, UAVs, aircraft, satellites and spacecraft can take advantage of these characteristics to help further enhance sustainability, economy, and performance.