Students prove EMC design techniques save time and cost

Here are the results of a practical laboratory exercise for undergraduate students, taken from: 'Teaching EMC using an EMC demonstration unit', a paper submitted for the 2018 APEMC/IEEE symposium in Singapore.

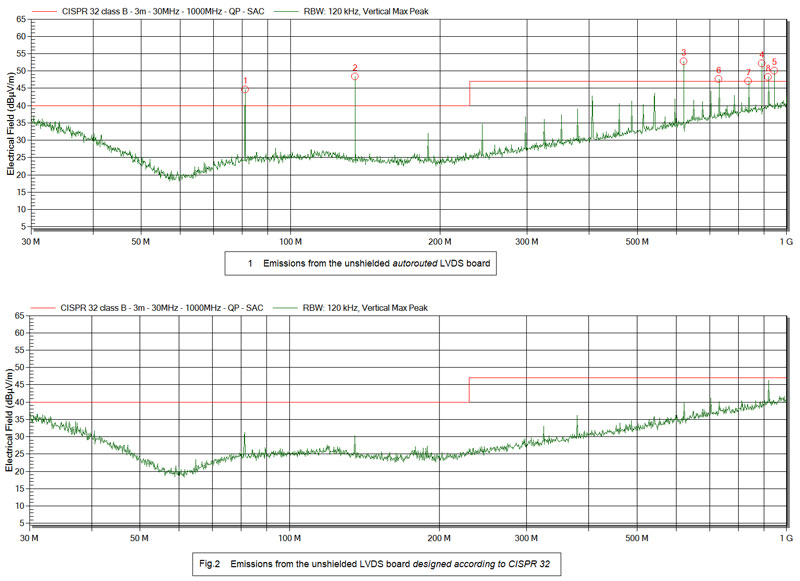

Students had to design a PCB for an LVDS driver circuit, using a commercial PCB autorouter. Then they had to lay it out again - this time applying our good EMC PCB design textbook. Both boards were tested to meet functional specifications, then their RF emissions were tested toCISPR 32 Class B limits in the University’s EMC Test Laboratory, with the results shown below.

Figure 1 shows that the autorouted board would need shielding and/or filtering adding to comply with Class B. If an unshielded plastic enclosure had been intended, it would have needed a design iteration, and re-testing.

Shielding/filtering is quite tricky to do at frequencies above 300MHz, so a second design/test iteration might have been needed before the product passed Class B.

However, Fig.2 shows that the board laid out using the guidance in the CISPR 32 would comply with Class B even in a low cost unshielded plastic enclosure.

Why suffer design iterations, with their delays, risks and costs, when even undergraduate students with no previous experience find it easy to use our good EMC design techniques to make products that pass EMC tests first time?

Since 1994 they have been proven time and time again, in numerous different industries and applications worldwide, to quickly and reliably give good cost effective results using only plain English and simple mathematics, avoiding the risks of under- and over-engineering.